-

Forage harvesters RSM F 2650

-

-

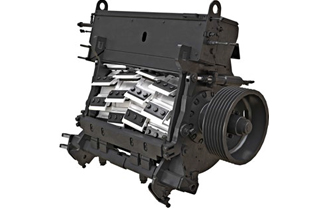

CUTTERHEAD

New cutting system was developed specially for F series machines. 48‑blades arranged in four rows in a chevron pattern.

- ● The cutterhead diameter is 630mm; rotation speed is 1 200 RPM;

- ● Half set of knives could be used to increase chopping length twice;

- ● Reinforced trunnions and bearings ensure reliable operation of the cutterhead;

- ● Cutterhead bed clearance is adjusted automatically;

- ● The new sharpening device doubles the speed of knives sharpening;

- ● Special knives for grass and corn harvesting are available as an option.

- ● The cutterhead diameter is 630mm; rotation speed is 1 200 RPM;

-

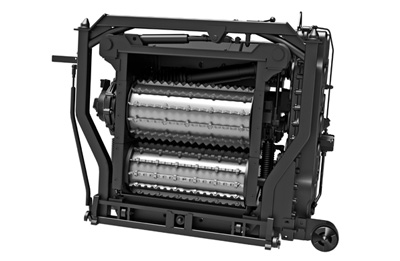

FEEDROLLS

Hydraulically driven feedrolls provide uniform material feeding and allow to adjust length of cut from the cab.

- ● The lateral tilt frame on the feedroll housing allows to copy the ground with any header attached;

- ● The length of cut could be adjusted from 4mm to 22mm with full set of knives or from 8mm to 44 mm with half set of knives.

- ● The hydraulic feed roll damper prevents damage to the feedroll housing absorbing impact loads while working with uneven windrows;

- ● For easy cutterhead maintenance the feedroll housing could be opened either V-shaped or gate-like.

- ● The lateral tilt frame on the feedroll housing allows to copy the ground with any header attached;

-

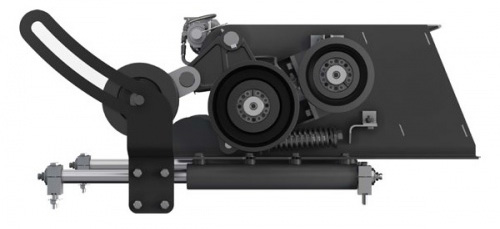

DRIVELINE

The gearbox and the mainclutch are installed at the engine drive shaft. The gearbox drives transmission pump, high and low pressure hydraulic systems pumps and header drive pump. The clutch provides direct power take-off for the cutterhead and blower from the engine crankshaft.

- ● Maximum efficiency of the driveline due to direct power takeoff from the engine crankshaft;

- ● The hydraulic header drive allows adjusting the speed of adapter on the go;

- ● The drive axle and electrohydraulically operated transmission allows the maximum transport speed of 40km/h.

- ● Maximum efficiency of the driveline due to direct power takeoff from the engine crankshaft;

-

KERNELL PROCESSOR

Switching from kernel processor to grass chute is operated by the hydraulic drive. The new slider design of the kernell processor does not require dismounting when switching to grass harvesting.

- ● Reinforced bearings improve reliability of the unit;

- ● Switching from kernell processor to the grass chute takes only 2 seconds and is controlled from the cab;

- ● Kernell processor gap could be adjusted from the cab.

- ● Reinforced bearings improve reliability of the unit;

-

INOCULANT DOSING SYSTEM

It can apply both concentrated inoculant in the range of 0.3 to 6L per hour, and diluted inoculant in the range of 10 to 300L per hour.

- ● The concentrateidn oculant tank capacity is 30L. The dilutedin oculant tank capacity is 390L;

- ● Three points of application are available – on the feedrolls to clean the chutes with water, in the blower for better mixing of the inoculant and in the spout when using corrosive concentrated inoculant.

- ● The concentrateidn oculant tank capacity is 30L. The dilutedin oculant tank capacity is 390L;

-

ERGONOMIC СOMFORT CAB II

F series combines are equipped with suspended Comfort Cab II with panoramic view and improved noise insulation. Once you are in, you’ll know how comfortable a workplace can be.

- ● The Adviser III voice information system continuously monitorst he combine operations, allowing to control the workflow and to prevent malfunctions;

- ● The operator’s seat with 5 adjustments;

- ● The cab is equipped with the climate control system and the beverage cooler;

- ● A new multyfunctional lever on the armrest makes controling the key functions easy and convenient.

- ● The Adviser III voice information system continuously monitorst he combine operations, allowing to control the workflow and to prevent malfunctions;

-

VIDEO MONITORING SYSTEM

The image from the camera on the spout (or from the camera on the rear hood when reversing) is shown on the display.

- ● Reduces losses of the chopped mass due to more convenient control of mass flow;

- ● Reduces operator fatigue, allowing simultaneous control over the combine movement and chopped mass unloading.

- ● Reduces losses of the chopped mass due to more convenient control of mass flow;

-

Headers

MAIZE HEADER SERIES

Drum headers for corn harvesting. You can easily select a header suitable for your yield.

● MH 450 – 4.5 m, 6 rows;

● MH 600 – 6 m, 8 rows;

● MH 750 – 7.5 m, 10 rows.

GRASS HEADER 600

A 6m wide rotary header.

● Work speed is up to 15 km/h;

● Shear safety elements on every rotor.

FOR UP 300 PICKUP

A 3m wide windrow pickup.

● The flexible frame of the pickup provides additional ground copying;

● The rear track roller protects the pickup mechanism on uneven fields;

● Friction and overrunning clutches on the drives protect the main pick-up mechanisms from overload.

-

Get a best-price offer for harvester

2450/2550/2650 -

* The terms of use of the site, you can find on this page Legal information.

* * The information published on this site is for informational purposes only, not a public offer.