-

ARGUS Corn Harvesting Headers

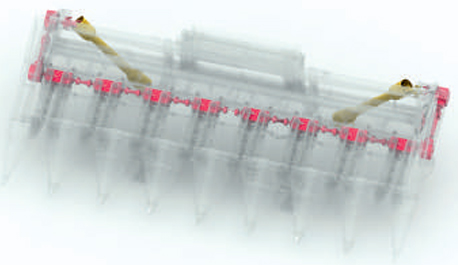

The high-performance 4-, 5-, 6-, 8- and 12-row Argus series headers are designed for harvesting technically ripe grain corn. The special design of the broaching rolls with adjustable gaps enables harvesting all stems of plants with a diameter of up to 50mm. The chopper located at the end of the channel contributes to a uniform cutting of stems leaving crop residues of the minimum height on the field. Under maximum operating speed of the harvester, i.e. 9 km/h, the loss behind the header doesn’t exceed 0.5%.

Harvesting grain corn with simultaneous chopping and distribution of the leafy-stalk mass throughout the field reduces the number of passes of the tillage machinery.

Smooth control and a special mechanism for overload protection ensure reliable operation.

Argus series corn headers can be aggregated with almost all brands of grain harvesters.-

number of rows (4, 5, 6, 8, 12)

?>

-

capacity up to 40 t/h

-

row spacing 70 and 75 sm

-

chopper

-

-

Qualitative benefits of the Argus headers

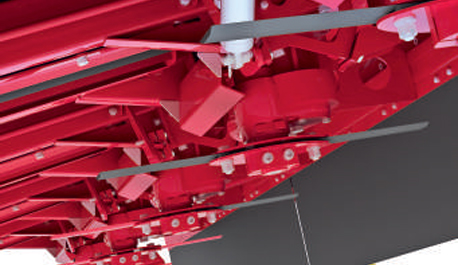

1. Chopping rational diagrams

The knives mounted on the rolls make a “splicing” of the stem along the fibers, and a rotary chopper finally chops the leafy-stalk mass. The result is particles with a length of less than 10cm, which enables subsequent tillage in a short time.

2. Adjustment to harvested varieties

Presence of movable detachable plates enables adjusting well to the stem diameter of the harvested variety. Settings are set from the operator’s workplace and ensure free passage of stems with a diameter of up to 50mm.

3. Energy saving

Small weight enables to aggregate with light- weight harvesters without installing additional loads. Energy is saved, pressure of the harvester wheels on the soil decreases. The spacer enables the Argus header to be assembled with virtually any harvester model.

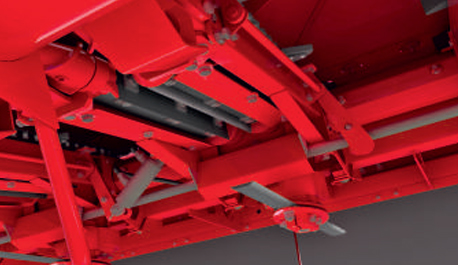

4. Increased durability

In case of extreme situations, reliable protection of the working elements is ensured by safety devices installed on the drive cardan shafts, on the auger drive and on each gearbox of the channel.

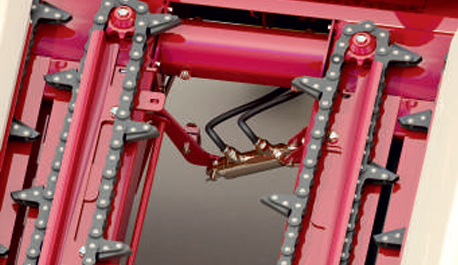

5. Improved drive characteristics

Drive actuated from bevel gearboxes, as well as a gearbox of stretching rolls and imported feed chains, increases the operational durability of all header units with reduced time spent on their maintenance.

6. Flexibility of operation

The adjustable gap between the knives of the stretching rolls enable considering both harvesting weather conditions and biological characteristics of the variety or hybrid of harvested corn, ensuring stable operation of the unit.

-

Get a best-price offer for

ARGUS Corn Harvesting Headers -

* The terms of use of the site, you can find on this page Legal information.

* * The information published on this site is for informational purposes only, not a public offer.