-

Forage Harvester RSM F 1300

-

-

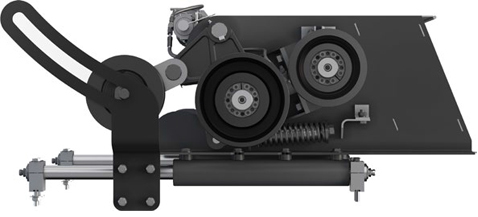

FEEDROLLS

Rugged design of the feeder guarantees its reliable operation at any yield. The feeder rollers are driven by a gear case developed by Rostselmash.

- ● The transverse contour following frame on the feeder enables ground contour following while working with any adapter;

- ● One of four cutting length can be selected: 4/7/10/17 mm with a complete set of blades or 8/14/20/34 mm with a half-set of blades;

- ● Wear plates installed on the feeding rollers combs permit changing the feeding rate of material;

- ● For ease of the chopping cylinder maintenance, the feeder can be opened either V-shaped or gate-like.

- ● The transverse contour following frame on the feeder enables ground contour following while working with any adapter;

-

CUTTERHEAD

The new chopping system featuring 48 blades arranged in a four-row chevron pattern was developed specially for F series machines.

- ● Cutterhead diameter: 630mm; rotation speed: 1,200 RPM;

- ● It can operate with a half-set of knives for increased chopping length;

- ● Reinforced trunnions and bearings ensure fault-free operation of the cutterhead;

- ● Cutterhead bed clearance is adjusted in unison with the shear bar clearance;

- ● The new sharpening device doubles the knives sharpening speed;

- ● Special knives for grass and corn are optionally available.

- ● Cutterhead diameter: 630mm; rotation speed: 1,200 RPM;

-

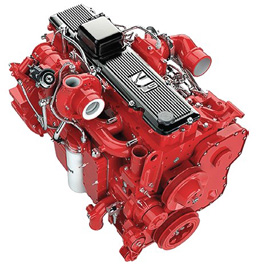

DRIVELINE

The cutterhead and crop accelerator are driven directly from the engine shaft via the main drive clutch.

- ● Maximum energy efficiency of the drive due to direct transmission of power from the motor shaft;

- ● The feed rolls gear case is belt-driven from the cutterhead shaft. This simple solution allows to synchronize the feed rolls and cutterhead speeds and maintain constant chopping length at any loads.

- ● Maximum energy efficiency of the drive due to direct transmission of power from the motor shaft;

-

KERNELL PROCESSOR

The crusher unit is engaged by the hydraulic drive. The new slider design of the crusher unit eliminates the need to dismount it when switching to grass harvesting.

- ● Reinforced bearings improve reliability of the assembly;

- ● Replacing the grass adapter by the crusher unit takes only 3 minutes in a semi-automatic mode.

- ● Reinforced bearings improve reliability of the assembly;

-

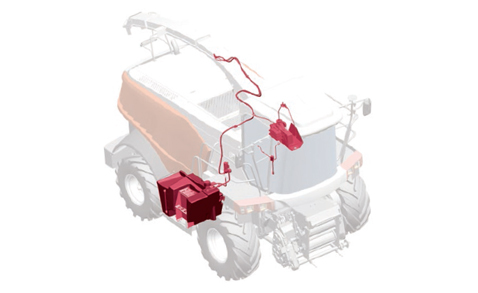

VERSATILE INOCULANT DOSING SYSTEM

It can apply both concentrated inoculant in the range of 0.3 to 6L per hour, and diluted inoculant in the range of 10 to 300L per hour.

- ● The concentrateidn oculant tank cap is 20L (2x10). The diluted preservative tank capacity is 390L;

- ● There are 3 points of application – onto the feedrolls to clean the chutes with water, into the crop material accelerator for better mixing of the inoculant, and into the spout when using corrosive concentrated inoculant.

- ● The concentrateidn oculant tank cap is 20L (2x10). The diluted preservative tank capacity is 390L;

-

MODERN ERGONOMIC COMFORT CAB

The ergonomic workplace provides the operator with a high level of comfort. The adjustable seat and steering column ensure the best posture. Controls are located in the direct access area to the right of the seat on the armrest and joystick.

- ● The Adviser II information system provides the required information on the combine’s performance, allowing to monitor process stability and optimum operation of the main assemblies;

- ● The basic package includes airconditioning, beverage cooler, and audio fittings;

- ● Panoramic glazing provides for excellent field of vision.

- ● The Adviser II information system provides the required information on the combine’s performance, allowing to monitor process stability and optimum operation of the main assemblies;

-

VIDEO MONITORING SYSTEM

The image from the spout camera (or from the rear hood camera when reversing) is shown on the display.

- ● Reduces losses of the chopped mass due to more convenient control of crop material flow;

- ● Reduces operator fatigue, allowing simultaneous control over the combine movement and crop material unloading.

-

FORAGE HARVESTING ADAPTERS

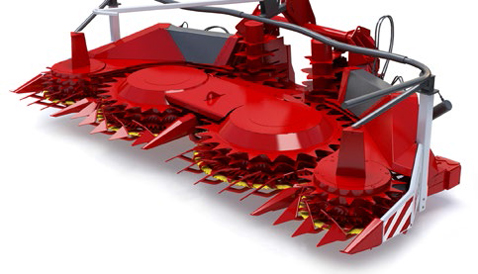

MAIZE HEADER 450

GRASS HEADER 500

Drum headers for corn harvesting. You can easily select the header suitable for your yield.

● MH 450‑4,5‑6.5m, 10 rows;

● Minimum cutting height: 60 mm;

● Width in transport position: 3 m.

Direct cut header; operating width: 5 m.

● Slip clutches installed on the reel and auger shafts prevent overloads of drive assemblies;

● The cutterbar with a Schumacher drive is simple in maintenance and provides high-quality cutting.

FOR UP 300 PICKUP

Drum-rake windrow pickup; operating width: 3 m.

● The flexible frame of the pickup provides additional ground copying;

● The rear track roller protects the pickup mechanism on uneven fields;

● Friction and overrunning clutches on the drives protect the main pick-up mechanisms against overloads.

-

Get a best-price offer

forage harvester RSM F 1300 -

* The terms of use of the site, you can find on this page Legal information.

* * The information published on this site is for informational purposes only, not a public offer.