-

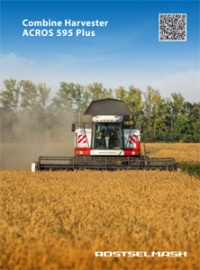

COMBINE HARVESTER ACROS 595 Plus

High productivity, universality, care of grain and straw, easiness of adjustments and comfortable work station – these are the merits for which ACROS combines are evaluated by agrarians all over the world. The series is represented by several models adapted for various operating conditions. When choosing ACROS, be sure, that you purchase the combine acknowledged as the best in its class.

The combine abilities allow to harvest more than 1000 hectares per season, starting from early cereals, and finishing with corn and sunflower.

-

1. ConturPro contour following system

?>

-

2. Feeder house with accelerator beater

-

3. Enlarged 2-stage cleaning shoe

-

4. Straw walker with increased area

-

-

-

5. Smart Launch. High-erformance unloading – always

?>

-

6. Waterproof grain tank

-

7. Comfort Cab II cab with Adviser III system

-

8. Engine unit Cummins 333 hp

-

-

-

9. Total control over chaff

?>

-

10. New straw chopper/spreader

-

11. Adapters

-

-

-

-

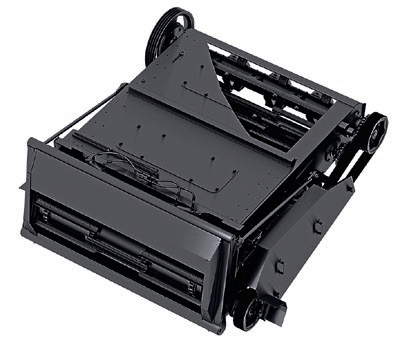

FEEDER HOUSE WITH ACCELERATOR BEATER

The feeder house now features an unrivalled solution – an accelerator beater at the conveyor output. Now all the material flowing to the threshing drum is not only spread evenly, but also accelerated. As a result, dynamic loads on the threshing system have reduced, and its throughput capacity has increased.

The feeder house has been made 250 mm longer for more uniform feeding of the material to the thresher and better view of the cutterbar. In addition, it is now easier to load/unload the header on/from the trailer. Yet another clear benefit for those who use the combine to harvest sunflower or corn is that since there is no front beater, you don’t have to retrofit the feeder house when changing over to combining tilled crops.

-

CONTURPRO CONTOUR FOLLOWING SYSTEM

ConturPro electrohydraulic ground contour following system facilitates the harvesting process since the operator no longer has to deal with uneven ground no matter what combine ground speed is.

Those operators who tried the system will agree that fatigue is much less, and ground contour is now the concern of the electronics that keeps it under accurate control. All contour following settings and adjustments are made from the cab.

-

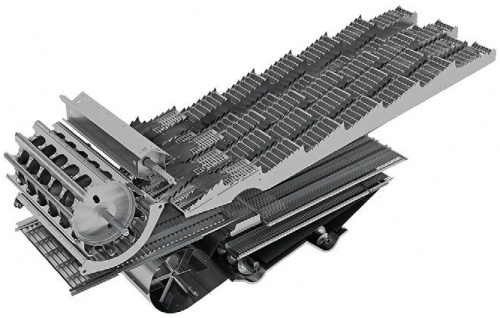

ENLARGED 2-STAGE CLEANING SHOE

The new cleaning shoe has now 2 stages: a precleaner and two air-blown height drop zones, delivering enhanced performance with the same length of sieves. The total area of the sieves has increased significantly – 5.2 sq. m versus 4.74 sq. m.

Another feature is a new 2-section fan with air intake not only at the ends, but also in the middle. The fan produces a strong and steady flow insensitive to sieve load variations.

The advantage of such cleaning shoe versus traditional design is a greater combine productivity and lower content of impurities & debris in the tank grain.

The improvement in cleanliness of tank grain is significant, so it can be delivered right from the field to the storage. Another advantage is the electrical adjustment of the sieves. Now you can make all adjustments of the air flow and sieve positions without leaving the cab. Moreover, for ease of maintenance the sieves can be instantly removed.

-

SMART LAUNCH. HIGH-PERFORMANCE UNLOADING – ALWAYS

Smart Launch is a patented device that consecutively starts separately the unloading and cross augers.

It offers the following benefits:

1) Reduces the risk of unloader damage due to overload at starting. This feature is particularly important when combining high moisture crops.

2) Prevents spillage of tank grain when folding the auger. The unloading tube always remains free from grain.

3) Unloading by portions is easy. -

WATERPROOF GRAIN TANK

When operating ACROS 595 Plus, there is no need for the operator to rush if it starts raining and there is no truck to unload into.

The grain in the tank will be securely protected by the special covers. Also, such solution ensures smallseeded crops that are easily blown out are retained inside irrespective of the strength and direction of the wind. -

_574ed7cd5caf3.jpg)

TOTAL CONTROL OVER CHAFFACROS 595 Plus combine equipped with a chaff spreader downstream of the cleaning sieves. Speed of spreader rotors is adjusted both from the cab, and from the outside by means of a flow valve. If you don’t need the spreader, you can easily and quickly detach it, and the hydraulic system will close the circuit. Chaff spreading is a key element of sustainable no-till and minimal till technologies.

NEW STRAW CHOPPER/SPREADERThe straw chopper/spreader for ACROS 595 Plus combines is in many ways different from lower range models. The chopping/windrow mode valve has been moved to the back wall of the chopper, and when swathing it directs the material in, rather than against, the direction of combine’s movement through an opening in the hood. This solution is more beneficial since when the combine is stopped while in the windrowing mode, the material will not build up under the chopper.

-

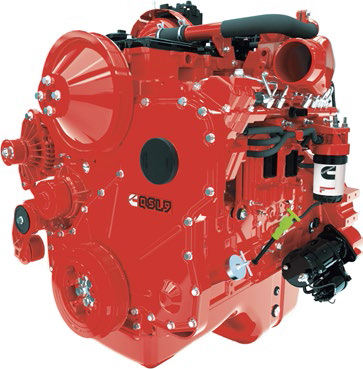

ENGINE UNIT CUMMINS 333 HP

ACROS 595 Plus is equipped with Cummins (QSL 9 , 6LTA8.9 ), (Stage IV, Stage III , Stage II), turbodiesel engine, in-line six cylinder with displacement of 8.9 L, 333 h. p. (248 kW at 2,100 RPM).

The operator can control engine easily with the button-type switch on the cab control panel. Torque reserve is up to 25 %. Powerful but rather compact, this engine provides a very modest fuel specific consumption. Air intake mesh with forced rotation (by hydraulic motor) is used in the intake air cleaning system. Air compressor in standard package.

-

COMFORT CAB II CAB WITH ADVISER III SYSTEM

-

-

ADAPTERS

-

_574ed950ebd45.jpg)

_574ed981b1ede.jpg)

CornIn order to harvest the corn seeds, the set of ACROS thresher re-equipment and 6- or 8-row snapper is proposed. The device provides harvesting of seeds with simultaneous shredding and throwing of leaf-stem mass over the field.

Sunflower seedsThe 8- and 12-row reapers especially designed for harvesting the sunflower shall provide the completeness crop harvesting at minimum rate of 98%, what is not achievable when using another type attachments. The reapers reliably operate in any agricultural conditions, including stunted sunflower hybrids.

_574ed9b60ab88.jpg)

_574ed9cd0ec6f.jpg)

In order to achieve maximum effectiveness when harvesting the easily-damaged cultures, the additional equipment is proposed. Rape attachment for reapers 6/7/9 m will reduce losses at harvesting by 3-4 times and additionally pick-up 30-100 kg of grain from 1 hectare of field, depending of crop capacity.

Rape

When harvesting seeds of legumes and cereals, it is possible to reduce considerably the seed losses and increase their purity, if the combine will be equipped with special attachment (“piercing” sieves, deck strip, etc.).

Small-seeded cultures -

Pickup attachment

In case of separate harvesting, the combines are equipped with pickup platforms having width 3.4 or 4.3 m. As the reaper, this device is able to copy the field relief in longitudinal and later directions. Reliable protection of pickup elements from clogging, winding and blowing-off the mass by wind provides its stable operation even in adverse conditions.

-

Get a best-price offer for combine ACROS 595 Plus

-

* The terms of use of the site, you can find on this page Legal information.

* * The information published on this site is for informational purposes only, not a public offer.

.jpg)

.jpg)

.jpg)

_1.jpg )

.jpg)